The Benefits of Six Sigma in Business You Should Know About

In all sectors including manufacturing, business, and corporate, the quest is always for enhanced efficiency and perfection. A minor defect can upset the entire output or outcome significantly. As a result, there is always a constant search for methodologies that can deliver excellent quality and results.

Six Sigma is one such methodology that companies use to minimize errors and maximize business processes improvement. This methodology continues to attract attention worldwide, with website resources like 6 Sigma offering comprehensive information and programs regarding the methodology.

But what exactly is Six Sigma, and what are the benefits of using it?

What is Six Sigma?

Six Sigma is defined as a set of techniques and tools for process improvement. It was introduced by American engineer Bill Smith while working at Motorola in 1986.

A Six Sigma process is one in which 99.99966% of all opportunities to produce some feature of a part are statistically expected to be free of defects. It is a quality-control methodology that uses empirical and statistical management methods to minimize variability in manufacturing and business processes.

Managements use this methodology's various tools and strategies to ensure greater operational output and efficiency. Anyone who uses statistics, project management, and financial analysis is a Six Sigma user.

And, any Six Sigma process is considered efficient when there are less than 3.4 defects per million opportunities (DPMO).

What the Six in Six Sigma Stands for

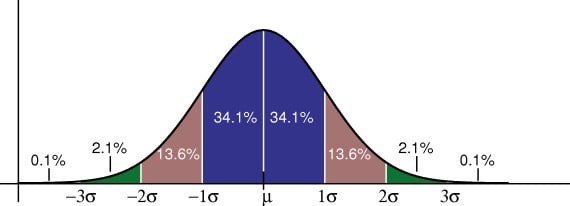

In statistics, there is a graph called the bell curve, which depicts the normal (bell curve) probability distribution that occurs naturally in many situations. It is known as a bell curve because the graph of its probability density looks like a bell.

An example of the bell curve is seen in tests like the SAT, where the bulk of students will score the average (C), a smaller number of students will score a B or D, and an even smaller number of students will score an F or an A. This creates a distribution resembling a bell (hence the name).

One sigma is a measure used to represent a standard deviation from the mean. When it is six, the variation is extremely low, and the sigmas can be adjusted on either side of the bell curve. When that happens, it is known as Six Sigma.

While the sigma can never be zero since the chances of having zero defects are almost impossible, the Six Sigma methodology calls for refining and bringing operations to a “six sigma” level, which essentially means 3.4 defects for every one million opportunities.

Benefits of Six Sigma Methodology

As you might expect, by collecting and using data and statistical analysis to implement the Six Sigma methodology in your business processes, there are many benefits you can get.

With Six Sigma, you’ll be able to reduce waste, minimize mistakes, and maximize value in processes, from management to manufacturing. That brings many advantages, including:

1. Greater Customer Loyalty

It has been found that Six Sigma helps retain customer loyalty and ensure they are satisfied at all times. A customer-oriented approach helps improve product quality, reduce mistakes, and encourage innovation.

Companies can also recognize the gap between the customer needs and a company's performance level. It also enables businesses to understand what products or parts of it offer the most satisfaction.

2. Saves a Lot of Time

Many organizations and companies prefer the Six Sigma method because it is highly productive and saves time. Before implementing the process, employees are asked to state their SMART goals and pursue them accordingly.

Businesses can use it to reduce the cycle time considerably. That is done by forming a team of employees across various departments and identifying factors contributing to long cycles.

3. Increases Overall Revenue and earnings

By using the Six Sigma DMAIC (define, measure, analyze, improve and control) approach, organizations can enhance their revenue through increased sales, cost savings, and fresh business opportunities.

Cost savings are achieved by removing the variability and cost of poor quality. There is an increase in sales when customers receive a qualitative output and continuous satisfaction.

4. Improves Supply Chain Management

Any manufacturing process or supply chain can only effectively work when there is consistency and reliability. Companies can do that by applying a Six Sigma approach, which helps reduce the number of suppliers and, consequently, the number of defects.

Any disruptions in the supply chain can be recognized while ensuring that the customer receives the right product at the right time with utmost efficiency.

Those are just some of the significant benefits businesses, organizations, and employees can get by incorporating the Six Sigma methodology in their processes.