How to Choose the Best Automated Sandblasting Equipment

Sandblasting is an effective surface cleaning technique with several industrial and commercial applications, including removing paint, rust, and other surface pollutants from cars, boats, heavy machinery, farm equipment, wood and log homes, and many other surfaces.

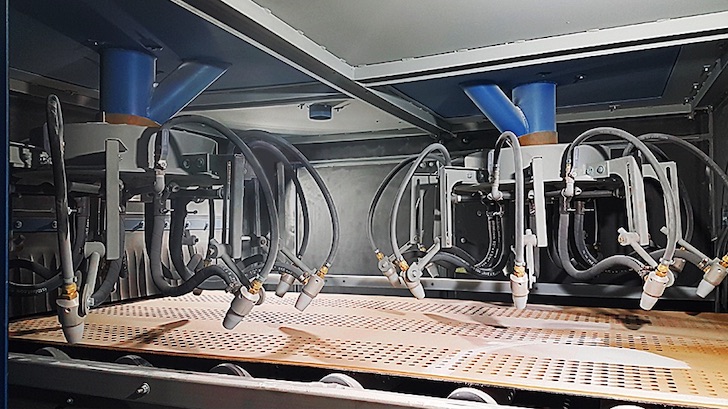

Also known as abrasive blasting, sandblasting entails the operation of a manual or automated machine to forcibly propel a stream of abrasive material against a surface to clean the surface.

Although they are more expensive than manual sandblasting equipment, automated sandblasting systems are more efficient and can make the job much easier. Despite this, finding the right ones can be tedious as you have to select the equipment based on several factors.

Manual vs. Automated Sandblasting Equipment

An automated sandblasting equipment helps in sandblasting of materials with greater throughput, quality consistency, predictable results, and reduced manual labor costs and employee fatigue over repetitive tasks.

Many high-end manual sandblasting machines are available to accomplish the task. But the process, when done manually, can be time-consuming and imperfect. With automated sandblasting equipment, however, you can speed up the process and make it more efficient.

Since sandblasting is a popular form of surface preparation used to remove unwanted material from the surface of a part, and there are many different automated sandblasting equipment available in the market that can speed up production time, minimize downtimes, and deliver predictable results, it can be challenging to pick the best one for your needs.

If you are looking to buy a fully automated sandblasting equipment for your workshop or factory, there are a few things you need to know about them before you make your purchase.

Selecting the Right Automated Sandblasting Equipment

Here are some tips to help you choose the best automated sandblasting equipment:

1. Consider the Material Being Blasted

When choosing an automated sandblasting machine, it is essential to consider the material being blasted. Different materials require different types of equipment. For example, softer materials may require a more pliant blast media, while more complex materials may require harder ones.

Additionally, the size of the material being blasted may also dictate the type of equipment needed. Smaller materials may need a smaller machine, while more extensive materials may require a giant machine.

Choosing what material to sandblast is the first step. There are several different types of sandblasting media, each with its benefits and drawbacks. Once you have decided on the kind of media you will be using, you can begin narrowing down your equipment choices.

2. Consider the Size of the Project

It is crucial to consider the size of the project when selecting an automated sandblasting equipment. For small projects, a handheld sandblaster may be sufficient. For larger projects, however, an automated sandblasting machine will be necessary.

Next, you need to consider the size of the job you'll be doing. If you only sandblast small items, you won't need a large industrial machine. Something smaller and more portable will be just fine.

On the other hand, if you plan on doing large jobs, you will need something that's up to the task. The size of the project will also dictate the size of the sandblasting cabinet.

3. Check the Speed at Which You Need the Material Blasted

Automated sandblasting equipment comes at various speeds, from slow to fast. When choosing a suitable machine for the job at hand, consider the rate at which you need the material blasted.

Low-volume automated sandblasting usually occurs in batch-type machines, while high-volume production usually occurs in continuous-type machines with loading and unloading conveyors to keep up with the desired production pace.

4. Consider Your Budget

Another important factor to consider when choosing automated sandblasting systems is your budget. There is a wide variety of sandblasting machines in the market that range in price from a few hundred dollars to several thousand. It's essential to find one that fits your budget and needs.

Look at your budget carefully and see what you can afford. There's no point in spending more money than you have but make sure you do not skimp on quality either. Find a balance between price and quality. This way you’ll find the best automated sandblasting equipment for your needs.

![9 Tips for Managing Your Online Writing Projects Efficiently [node:titile]](/sites/default/files/styles/thumbnail_rectangle/public/open-book-laptop-online-writing-tips.jpeg?itok=iq4PIT7b)