Injection Molding Business: Tips to Find the Best Injection Molding Service

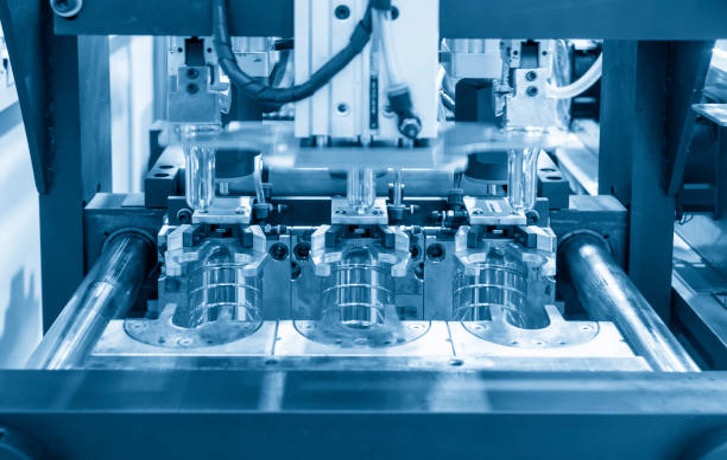

An injection molding company is a business that creates products by molding plastic pellets into various shapes. The company will have machines that heat the pellets until they are melted, and then inject them into a mold where they cool and harden into the desired shape.

Injection molding is used to make common consumer items such as cups, bottles, toys, lids, caps, kitchenware, and many other household goods and items. It can also be used to make more specialized items, such as automotive parts, complex electric housings, and medical devices.

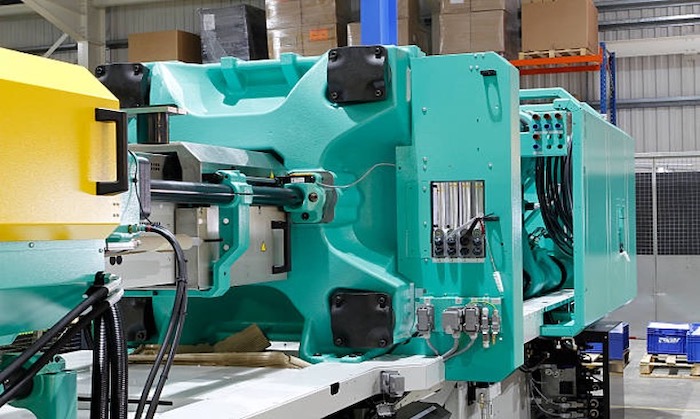

In order to get started in the injection molding business, you will need some basic equipment including an injection molding machine, molds for your products, and plastic pellets to use as raw material. You can find all of these items at online retailers or industrial suppliers.

With significant investment, you can start your own injection molding company and begin mass producing high-quality products for sale. Alternatively, you can opt to hire injection molding service providers to produce various products for you that you can sell to consumers around the world.

When looking to hire companies that offer injection molding services, it is very important that you select a company that is best suited for your needs. You want a company that has the right equipment, experience, and expertise in producing the products you’re looking to sell.

Here are some tips for selecting the best company offering injection molding services:

1. Look for an Experienced Injection Molding Company

Any business that relies on injection molding to produce its products needs to choose its injection molding company carefully. Injection molding is a complex process, and it takes a great deal of experience and skill to do it properly.

As a result, businesses should look for an injection molding company that has a track record of success. The best way to find out about a company's track record is to ask for references from other businesses that have used their services.

In addition, businesses should look for reviews of the company online. By taking the time to research potential providers, businesses can ensure that they choose an injection molding company that will meet their needs and expectations.

2. Ask for Sample Products from the Company

When applying for a job, it typically involves writing a resume and submitting it to various companies for consideration. Your resume is like your portfolio; it should be an accurate reflection of your skills, experience, and qualifications.

The same applies when you are seeking a quotation from an injection molding company. When inquiring about the cost of sample products, make sure to ask for their portfolio as well. Doing so will allow you to evaluate the quality of their work before committing to anything.

It’s best if you ask for a reference list as well. This way, you can speak with other clients who have worked with the company and get first-hand feedback about their service. Don't forget to inquire about the turn-around time for the sample product too.

By taking all these factors into consideration, you can be sure to choose the right injection molding company for your needs.

3. Check If the Injection Molding Company Has an ISO Certification

An ISO certification is an international standard that organizations can use to ensure that their products and services meet the highest quality standards. ISO certification is a voluntary process, but many companies choose to undergo ISO certification to demonstrate their commitment to quality.

There are a variety of ISO standards, each of which covers a different aspect of quality management. The most common ISO standards are those for quality management systems (ISO 9001) and environmental management systems (ISO 14001).

Before you allow any company to handle your injection molding needs, you should always check if they have an ISO certification. The International Organization for Standardization sets standards for products, services, and systems.

An ISO certification means that the company adheres to these standards and produces high-quality products. Many companies will display their ISO certification prominently on their website or other marketing materials. If you can't find it, don't hesitate to ask.

A company that is proud of its certification will be happy to show it off. And if they don't have one, that's a red flag that you should look elsewhere.

4. Confirm the Company Uses Modern Equipment and Up-to-Date Technology

When looking for an injection molding company, it's important to make sure that they have modern equipment and up-to-date technology. This ensures that they can produce high-quality parts and components that meet your specific requirements. It also means that they're able to work with a variety of materials, including both traditional and innovative plastics.

In addition, a company with modern equipment is more likely to be able to provide quick turnaround times, so you can get your products to market faster.

Therefore, when you're considering an injection molding company, be sure to ask about their equipment and technology. You'll be glad you did.

5. Get Quotes from Several Injection Molding Companies and Compare Pricing

In order to get the best deal on injection molding, it is important to get quotes from several different Injection Molding companies. Getting quotations will allow you to compare pricing and find the company that provides the best value for money and meets your needs.

When getting quotes, don’t forget to ask about the company's experience, turnaround time, and price. You should also ask for a sample of their work. By taking the time to compare prices and services, you can be sure to find the best company for your injection molding needs.

In Conclusion

Injection molding is a lucrative way to produce products in large quantities that you can sell and make profits. By following the tips we’ve outlined above, you should be able to find a company that can help you bring your product to market quickly and efficiently.

Be sure to get quotes from several companies and compare pricing before making a decision.